Lifting

The square platform of the pyramid was located at the foot of a sub-horizontal declivity plateau. One can deduce that the first layers could have been built from ground level and by using a ramp until a good height, perhaps even to the Pharaoh’s room. The blocks could very well have been drawn on sledges or rather floated far on the platform after having built the sides of a channel and seal this one. Once the channel built, it was enough to raise the sides, seal them and add blocks on the bottom of them so that the water level goes up to the following layer.

A log 15 cm in diameter, 1,5 m length weights 18,6 kg; it is supposed that one needs at least five of them to move a 2 m length sledge, loaded with a 2,5 t block and that at every 70 cm each log is carried from back to the front of the sledge so that this one can roll continuously. This operation requires from three to five men for the logs transport, as much to tow the sledge on flat ground and perhaps the double on sloped ground whereas the load must be blocked while going up to prevent its retreat and hold while going down to avoid the racing. Thus the use of logs can be considered for very short distances, but must be discarded for averages and long distances.

To move the blocks from one layer to another, one could very well build a slope, use brackets or cantilever beams for short distances inside the platform in progress. However, it is unthinkable to build external or interior continuous ramps, from ground base to the top, to move blocks. Slopes of 2% and 7% would have respective lengths of 5,8 and 1,7 km up to 110 and 120 m height, which is physiologically and technically impossible. No one can haul on a rope which crushes his shoulders, compresses its rib cage and reduces its breathing on a long way, during hours, in full sun, even less during months and years.

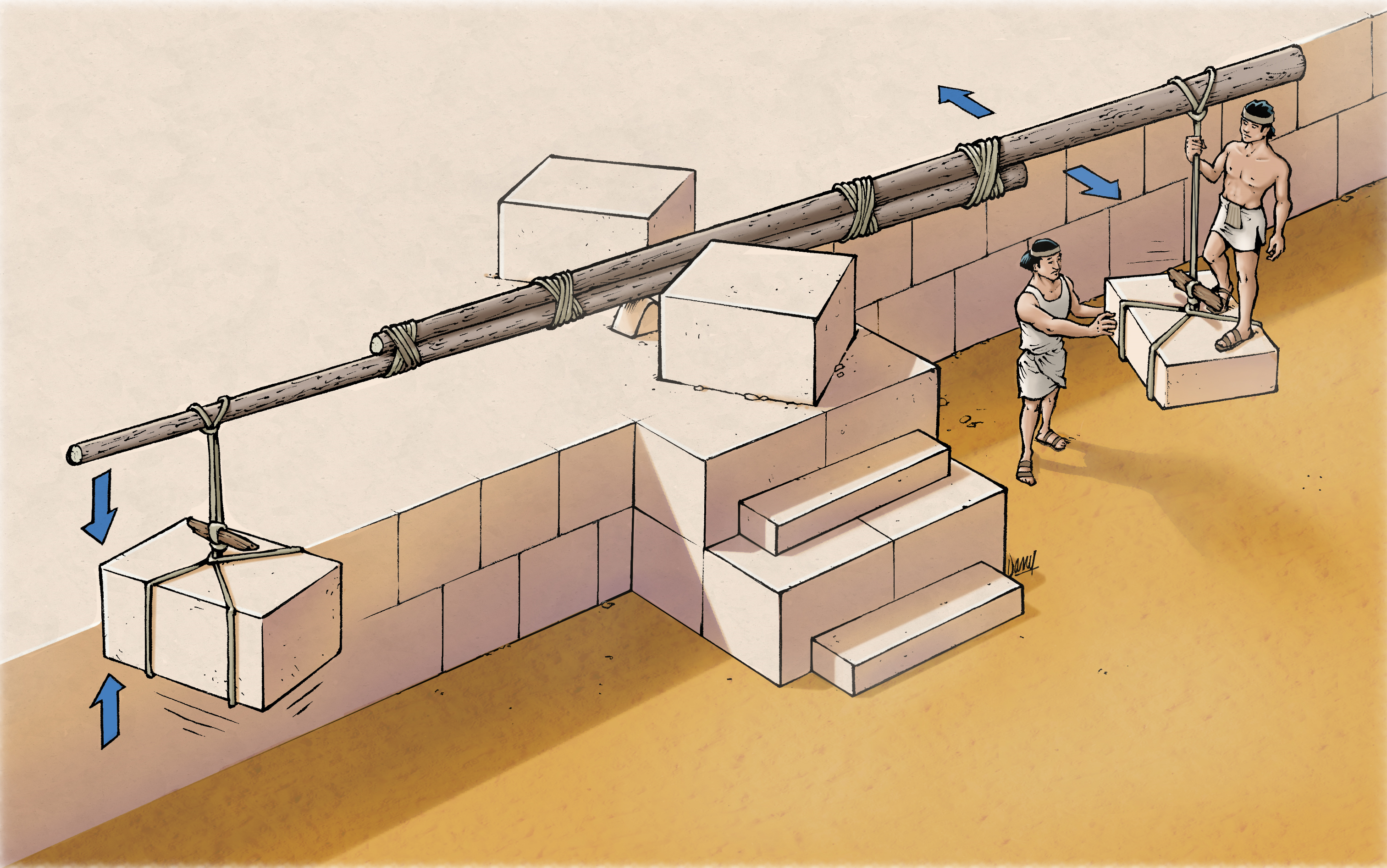

A simple and effective means to move blocks from a layer to another, overlying or subjacent, consists in using a bracket manufactured of two whole tree trunks, bounded, spliced on 1,5-2 m on both sides above a support. Each end of the splice is surrounded by a tightened rope, a lashing, on 60 cm and wood wedges are inserted under the cord, on each side of the trunks, to tighten it and prevent the rotation of the trunks. The support must be rudimentary, available or mobile everywhere on the platform, taking into account the number of stones to be moved. It can consist of two supported blocks side to side on which one installs two other blocks, turned of 45 degrees, brought closer by the corners and leaving a 30 to 40 cm window between the two; the shelf of this window is made up of a half moon shaped stone to facilitate the vertical beam movement up to more or less 15 degrees, and its horizontal rotation up to 45 degrees on both sides.

Dessin : Dany Lavoie

By installing two 25 to 35 cm tied beams in this window, they are supported laterally while having a possibility of rotation of almost 90 degrees. A counterweight, equivalent to half weight of the block, is attached to the upstream part of the beam so that only half of the weight is implied with each lifting; the two ends of the beam are equipped with guide ropes (stabilizing cable, tag line) to facilitate the lifting of the counterweight and then after the weight. This solution preserves trees intact until breaking, in which case, they are cut out and squared to produce less dimension parts.

A three strands loop is rolled up around at the end of the beams, like a Prussik node, in order to leave a hanging braid, which fits around the ankle left in the loop which girdles already the block. From the moment the stone is hauled in place under the braid, its stowing, lifting, rotation and deposit on a sledge at the higher level can be done in less than one minute. It is thus to say that a block could be raised on several successive levels in a few minutes by a series of aligned and coordinated lifting devices. One could think of using the elevating lifting devices per pairs, in opposite, to reduce as much stress on the parts, and so dimensions of those, and to proceed in several lifting points on the same face or side.

The blocks weighing up to 60 t brought by boats could be left on those and be floated until the center of the pyramid in a channel or an enclosure planned to this end for several boats. To adjust the height of the enclosing walls it was enough to add blocks on the bottom to control the water level to bring the boats and their contents to the good level, at the good place. This solution could very well have applied up to the level of the Pharaoh’s room at the rise 42 m, whereas 2 000 000 blocks were already set up. Above this height, only the lifting beams would have been used on several faces, on both sides of the core.