Blocks

In addition to the facing blocks and the red granite of Aswan, the limestone blocks could only come for a small part from the immediate environment of the pyramid; hills and caps were shaven, the beautiful limestone layers of the plateau were used before attacking major open quarries, more distant which finished by being submerged by sand or water. The blocks, by their nature, are intended for a single and final use, to belong to the body of the pyramid; the extraction will not be treated and the transport poses great challenges. Current knowledge suggests that for long distances, the blocks were transported by boats, whereas at small distances, they were transferred onto sledges drawn by men.

At the construction beginning, the north-western corner was the center of a provisioning circle whose ray cumulated 230 m to reach the pyramid, from 500 to 1000 m to reach the first quarries as far as it is in the vicinity, perhaps another 200 m to move in the quarries. A short distance thus measures from 1,0 to 1,5 km. By considering that a small percentage of declivity towards the pyramid would reduce of as much the coefficient of friction and that cross-pieces levelling to every 60-70 cm in uniform sands would prevent the sinking, 40 teams of 10 men each could have hauled 360 blocks per 12 hours day.

This tempo being foolish, one could rather have thought of claiming that 80 or 120 teams of 10 men chacunes hauled 360 blocks, as from a few hours before the daybreak and during four to six hours for then taking a rest and turning over in quarries to cut, or trim the blocks. This alternative imposes that the blocks were trimmed in career before being moved by an army of workers. In the absence of other solutions, it is still that privileged.

As for the idea to wet the sand to reduce the friction, it was always known that water adds a cohesion force to the granular ones, but this solution is applicable only on short distances, for the final blocks adjustment whereas the obstruction of the site tolerates the presence and the expertise of only few people. At long distances, the quantity of water would require more people than required to haul the blocks, with the risk to transform certain places into mud pits. This solution, as demanding as the preceding one, is not very productive either.

Let us take again the assumption that the decision to float the blocks was made since the design, that each block extracted, in outcrop of the ground along a planned course, contributed to dig a segment of channel, which was to go from the site and continue to the pyramid heart. From there to think that between Aswan in the south and Giza in the north, extraction sites could have used rivers, natural or dug channels in the ground to transport the blocks, there is only one step. Insofar as the channels are lined with clay to prevent seepage, the water level is stabilized by regulation works.

The blocks density varies from 2,5 to 2,7 for a mass variation from 2,5 to 2,7 t/m3. Submerged, the blocks are subjected to the Archimedes’s thrust and their residual mass varies then from 1,5 to 1,7 t/m3. If the blocks could have been fixed on any floating elements to be transported, their gravity centre would have been lower than the thrust center to ensure stability and it is the equivalent from 35 to 40% of the mass which would not have required energy for its transportation; so, imagine that brought back to the whole pyramid.

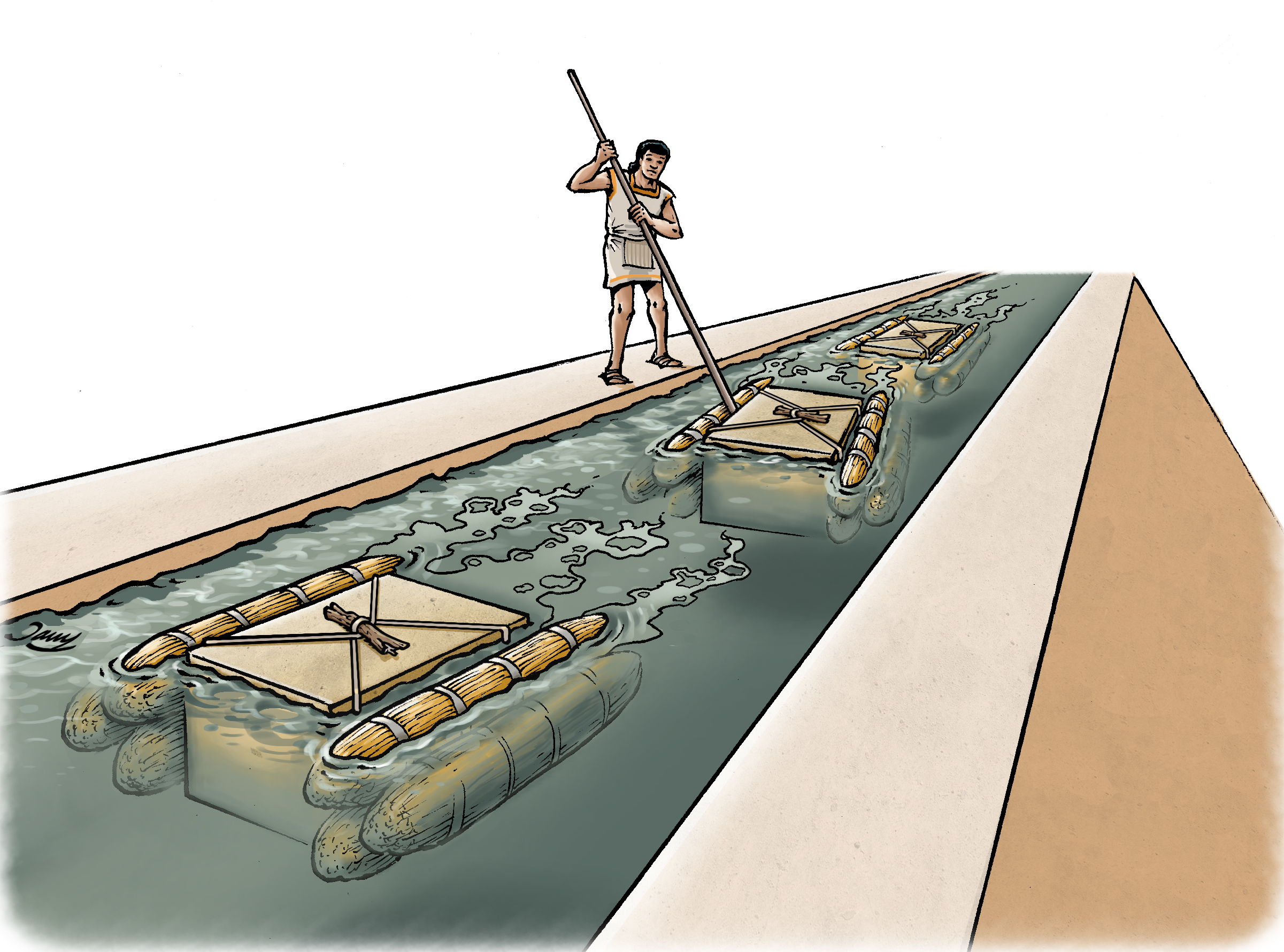

We suggest that two floats, each made up of three reeds beams, 30 cm in diameter, 3 m length, were sufficient to support a block submerged in a channel 1,2 to 1,4 m deep. These floats were tied together by two ropes and were maintained distant of approximately 2 m; girdled of its strap, each block, was sited on the two ropes which were then submerged by bringing closer the two floats; the straps were left in place and locked by a 10 cm diameter ankle warhead shaped at both ends.

These blocks would then have been drawn per few men or animals, day or night from a tow path, along the channel to the foot of the pyramid in preparation for their installation. A continuous flow in the channel would have been enough to float the blocks until the site of Khufu with a minimum of intervention; at most, from time to time, an operator with a pole would realign the blocks in the channel to prevent any jam.

Dessin : Dany Lavoie

Certain boats used in Egypt required draught of only 60 cm for of channel width of less than 2 m. Other boats have had 1,5 m draught like the one still being today at the foot of the pyramid. The most widespread opinion wants that the heaviest blocks coming from Aswan were charged on flat-bottomed boats, floated on the Nile to the port at the foot of the pyramid, were discharged on sledges and drawn up to the pyramid. The unloading operations were complex, this is why we believe that after having left Aswan, the boats borrowed a diversion channel to reach the plateau, to join existing channels and benefit from the flow caused by the declivity to go even to the centre of the pyramid.

The plateau being inhabited, floating and hauling of which we spoke previously could very well have been executed day or night in order not to accumulate any block at damping; at most, at destination, the limestone blocks exceeding the daily needs were piled up to create an access ramp on the southern side. Progressively with its rise, the top of the ramp was re-built as channel, a perched aqueduct, to bring the blocks to the center of the pyramid, and especially in preparation for the transport of the core large blocks. At final, this ramp would have had a volume of 140 000 m3, enough to complete the pyramid above the rise of 90 m.